Deslagging

"Removing a stony waste piece formed during metal melting."Removing metal slag refers to the process of eliminating slag, which are impurities and contaminants, from molten metal. Slag accumulations of molten steel at the cutting edges of the product. The metal slag causes height variations on the products, resulting in an undesirable outcome.

The removal of metal slag is essential to ensure the quality and purity of the final product. If slag is not removed, it can impact the properties of the metal and lead to weak points, porosity, or other defects in the finished metal.

Together for the best slag removal solution

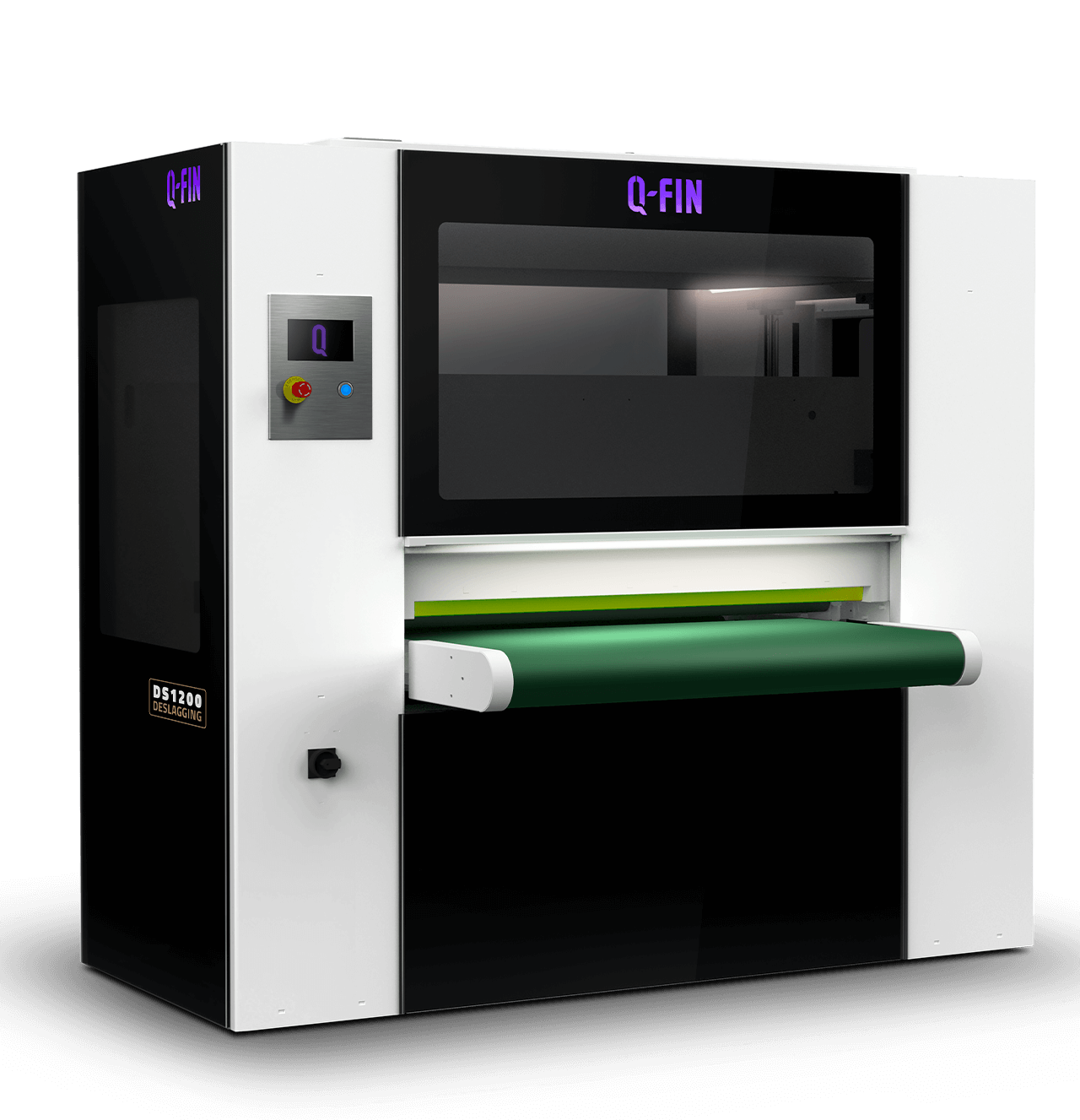

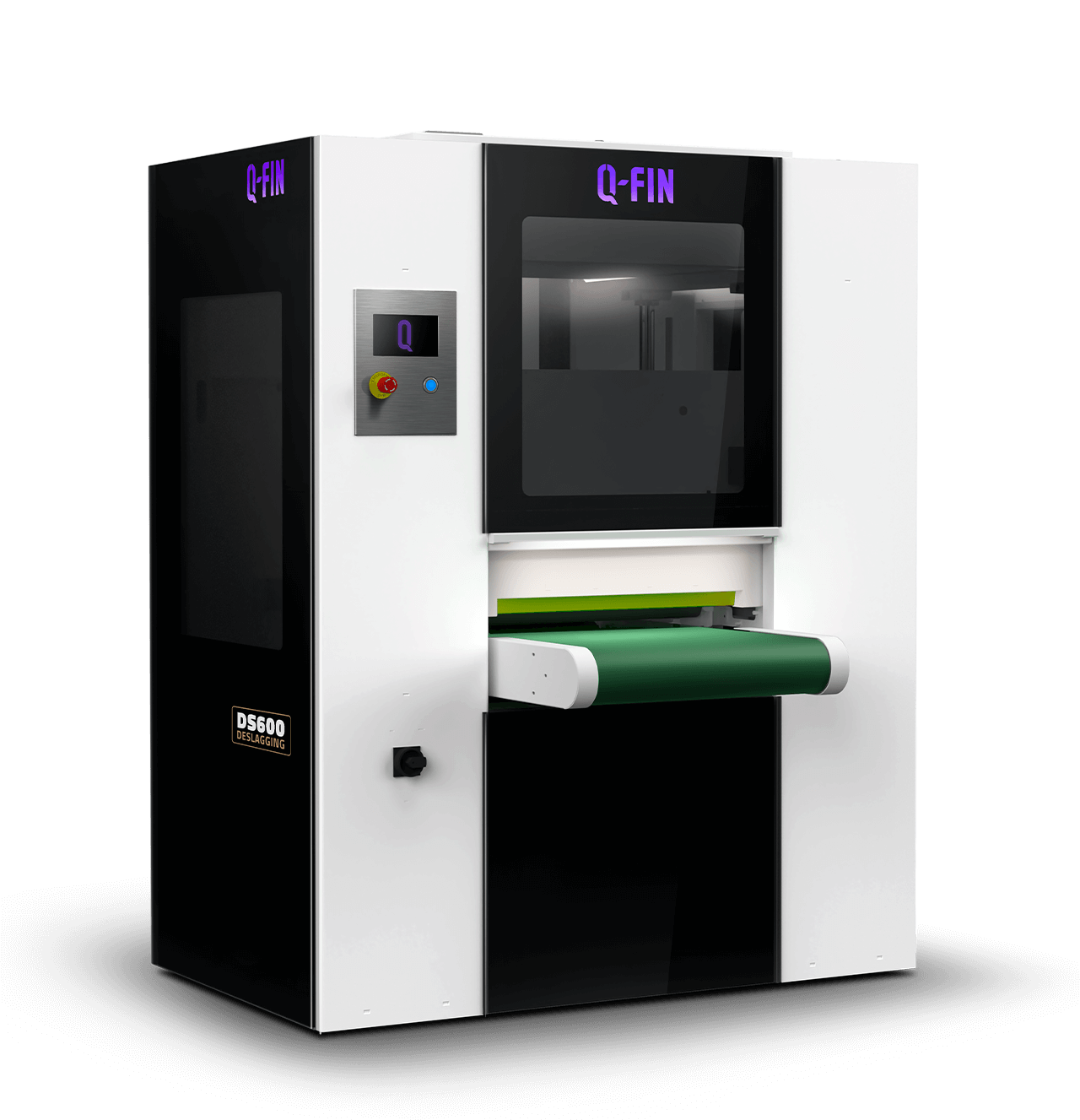

In practice, metal slag is often manually chipped off from the product, which is time-consuming and labor-intensive. Q-Fin offers two innovative automatic machines for effortless slag removal. With the DS600 and DS1200, you can remove slag from your steel sheet parts in a single pass. The products can then be post-processed in our finishing machines.

Why deslagging with Q-Fin?

- Removing slag effortlessly

- Increase in productivity

- Safe and ergonomic

- Slag removal and post-processing in one line possible

Test your product in our showroom

Are you interested in one of our machines but want to see it in action first? Then schedule a non-binding demonstration in our showroom. Alternatively, you can also send us your own products for a remote demonstration. Contact us for more information, and we will get in touch with you to discuss dates and options.