The benefits of a deburring machine for your company

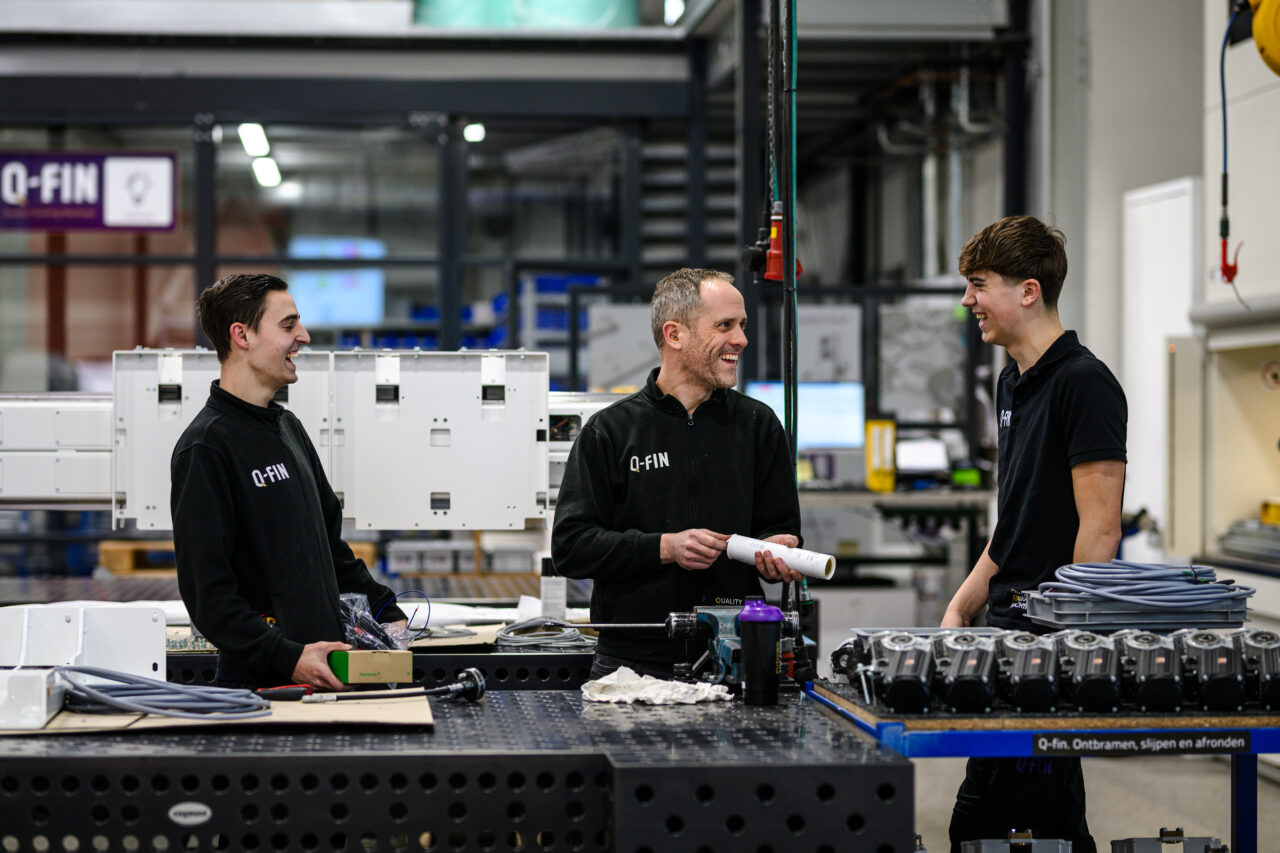

A Q-Fin deburring machine does more than improve product quality, it transforms the way your team works. By automating heavy, repetitive finishing tasks, you reduce physical strain and create a safer, more pleasant working environment.

Our systems take over the tough, time-consuming work so your colleagues can focus on higher-value tasks that require skill and attention. The result is a workplace with more comfort, consistency, and confidence, where people and machines work together to achieve the best results.

And of course, automation brings measurable benefits: consistent top-quality finishes, shorter lead times, and increased profitability. With Q-Fin, you’re not just investing in technology. You’re investing in your people and your future.