Health and safety is a major factor in todays workplace and the day to day use of machinery should be monitored carefully for wear and tear. Metal pieces of equipment are no exception to the rule and, although designed to withstand extreme pressure, will only last so long without careful maintenance. Here at Q-fin, we have the ideal solution for this, with our edge rounding machine.

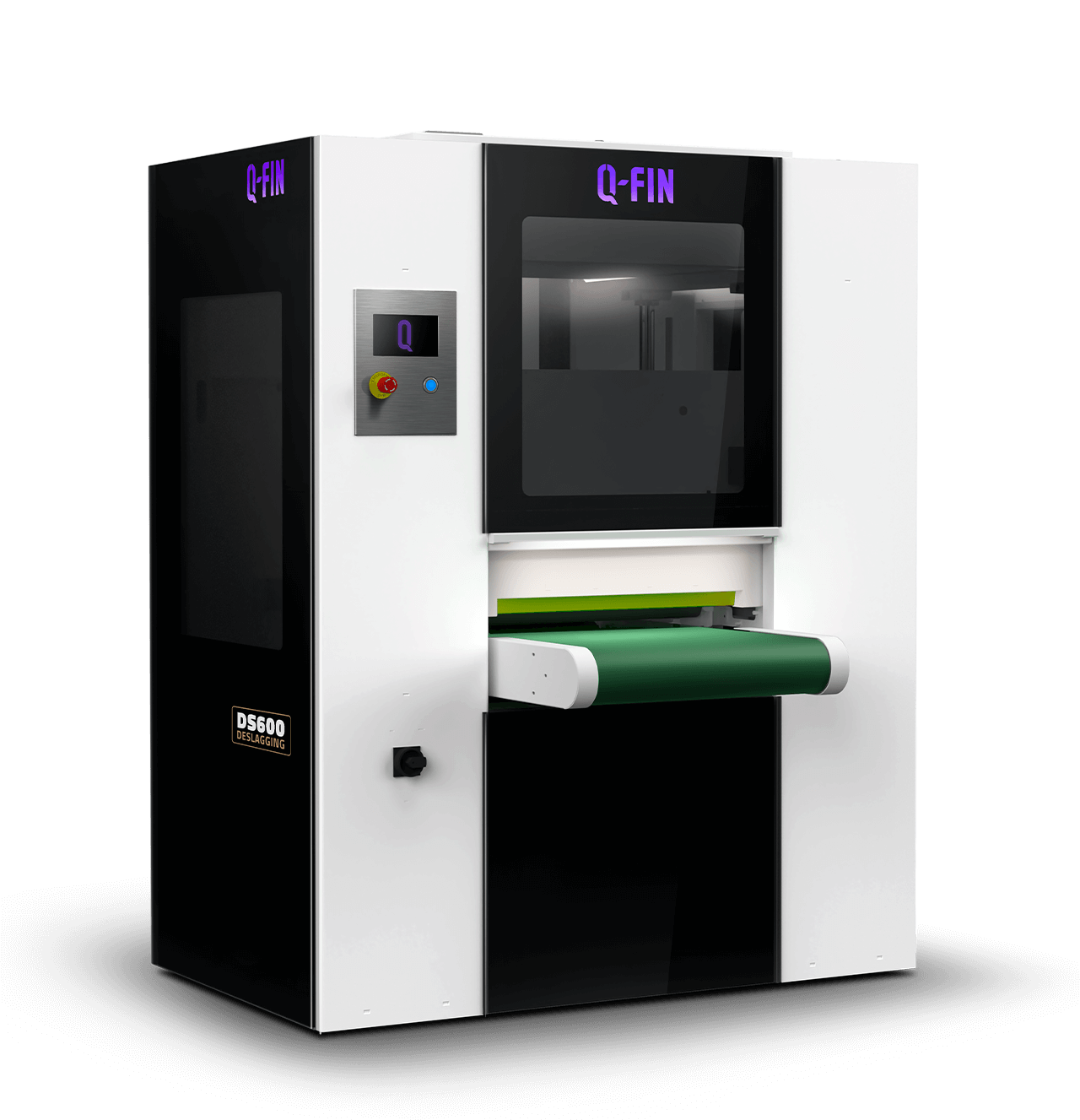

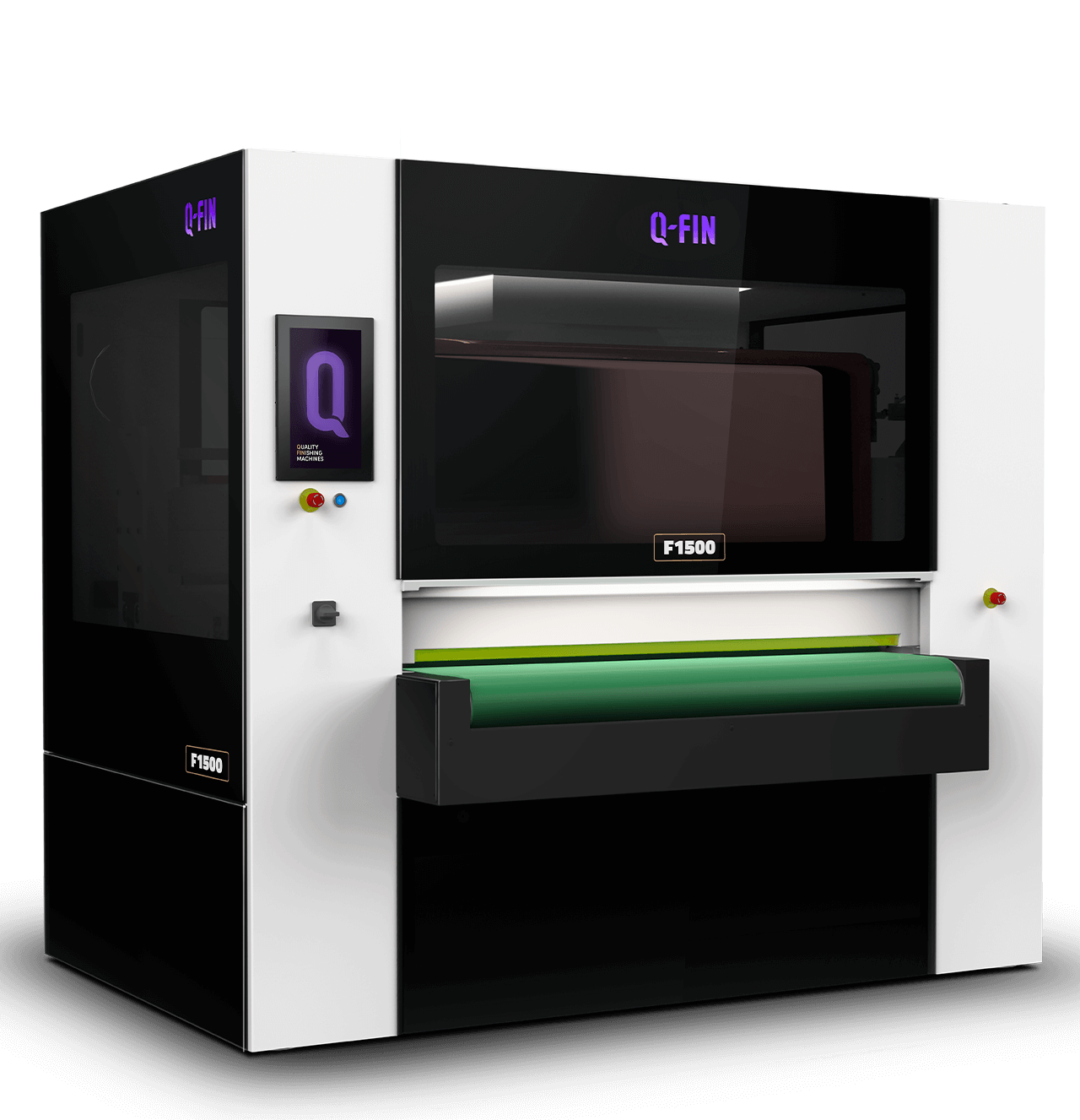

Our rounding edges machine has been designed with this exact problem in mind. It can carefully re-sculpt the edges of the worn equipment, preventing the need for brand new, expensive replacements to be purchased and allowing production to continue. The investment of an edge rounding machine can save not only your equipment but can prevent lost business. It can also ensure that all products are produced to the highest standard and are not left ruined by damaged edges.

Burring and wear on machinery, not only harms your business but can, if left, cause some rather nasty injuries in the workplace as worn machine parts can become extremely sharp in places. These can cause a severe health hazard to employees who have to handle them on a day-to-day basis. At worst, this could lead to a nasty injury and at best it could lead to extra care being taken to handle damaged items. This would slow down production times and reduce efficiency in the workplace.

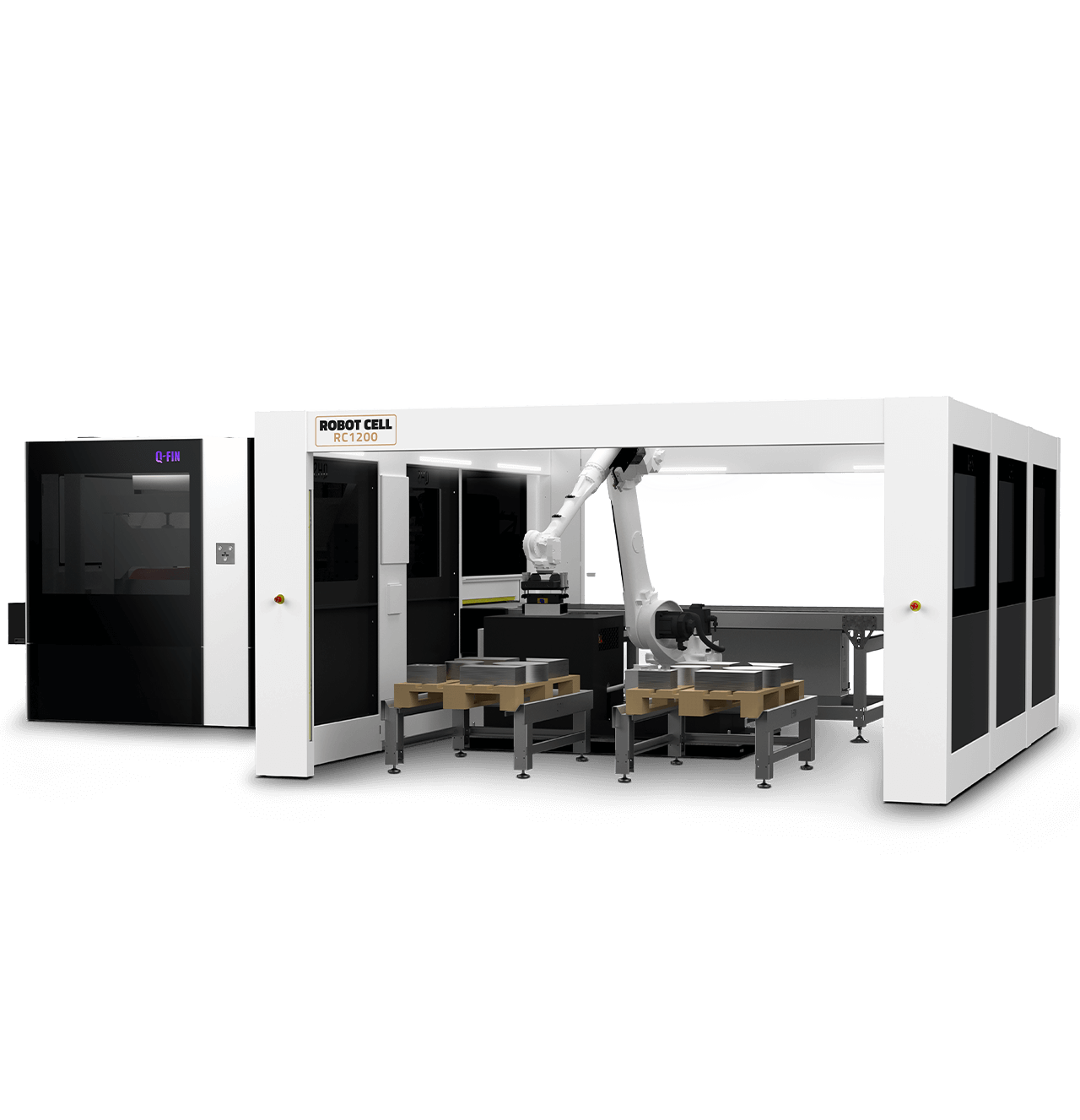

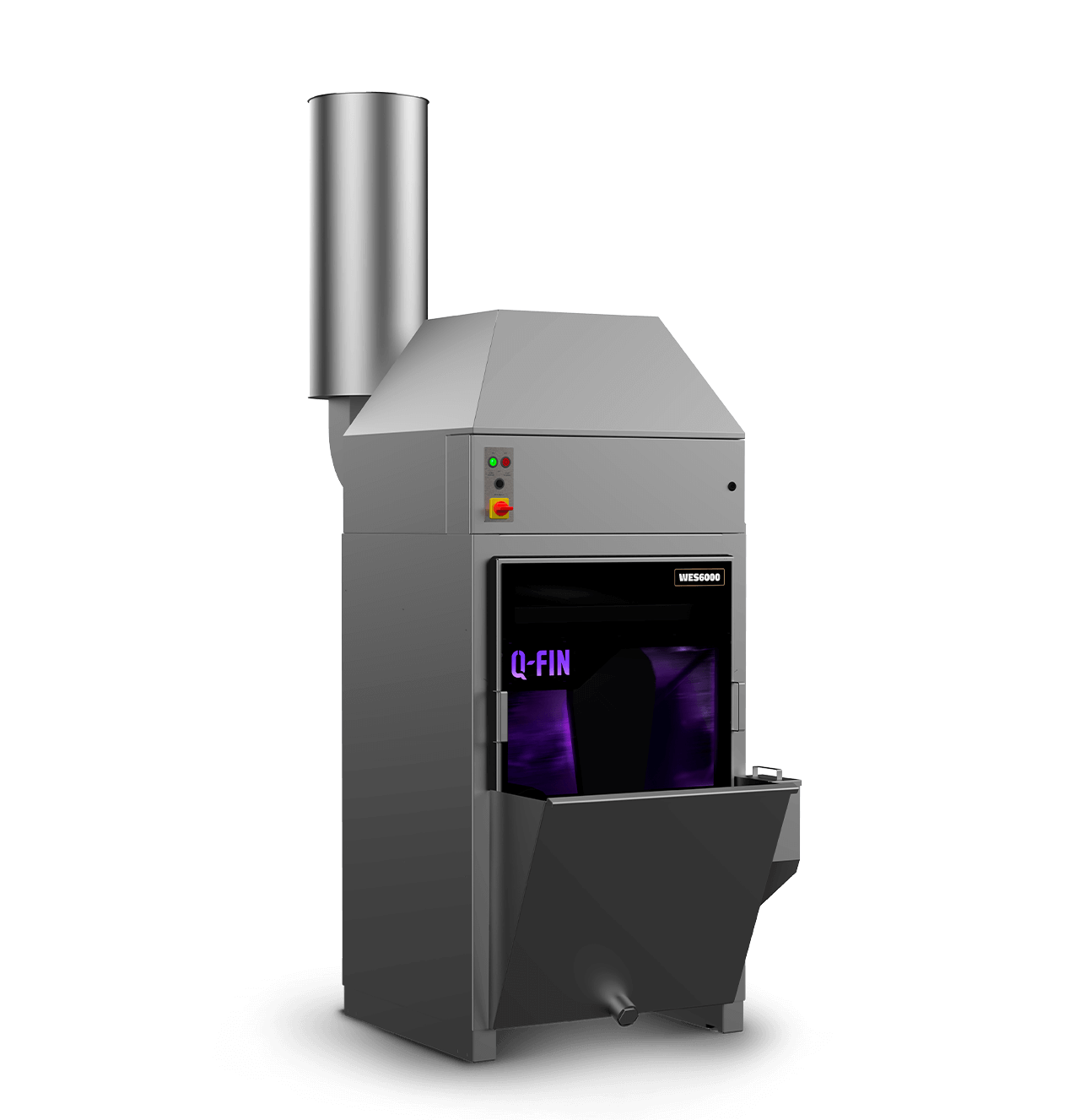

Our rounding edges machine is a very cost-effective solution to a potentially serious issue. The machinery can adapt to suit your situation, applying a fast and consistent solution. It is suitable for both crimping and rounding and can be adjusted to size. Our equipment provides real value for money with a three-in-one combination that can be used for deburring, grinding and rounding, all with one single outlay.

For more information, or advice on the best solution for your business, contact us today and ask for more details on our machinery.