Customer story

Haimerl Lasertechnik, LeonbergA flexible solution for a flexible metal company. See how Haimerl is prepared for the future.

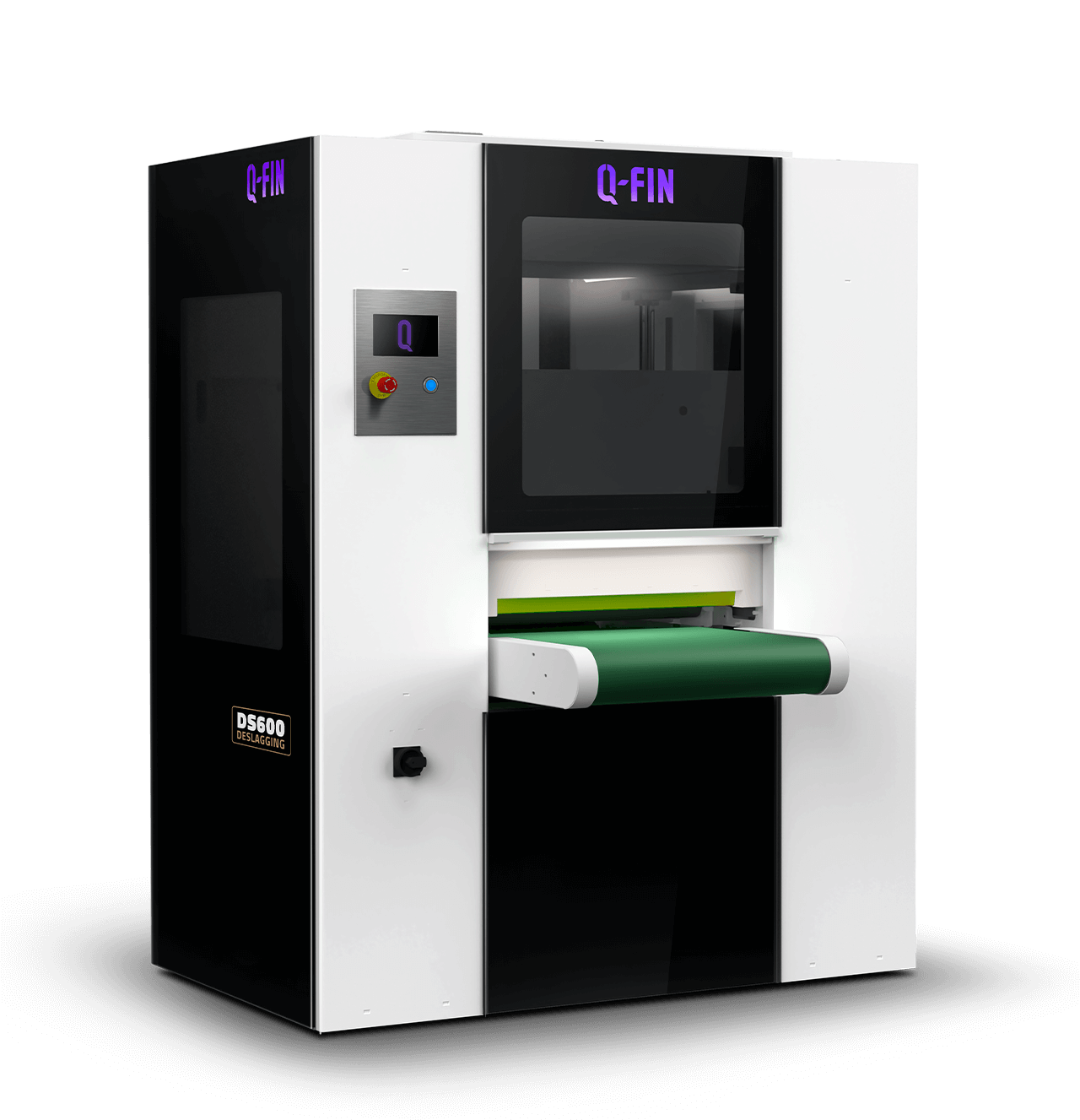

Stand-alone slag hammer for removing heavy slag

Let your team work finer and faster with the DS600. Our unique standalone solution removes slag from sheet metal parts up to 600 mm wide. This prevents damage and contamination in your production process.

I would like to receive the detailed technical specifications of this machine.

"*" indicates required fields

Q-FIN Quality Finishing Machines

Wilgenakker 8

5571 SJ Bergeijk

The Netherlands

t. +31 497 58 10 18

info@qfin-deburring.com

Deslagging is a labour-intensive, dirty job which still often involves the use of a hammer and chisel. Or an electrically powered hand-held machine is used. Because of the heavy workload for both the operator and the hand machine, these hand machines have to be replaced regularly. This causes high costs, an extra waste flow and possible health problems (e.g. HAVS) for the operator.

The DS600 and DS1200 were developed by Q-Fin to automatically remove slag generated during plasma or oxy-fuel cutting. These compact machines can be easily integrated into any production line. They remove the slag before the product reaches the deburring machine for edge rounding, optimizing the production process and enhancing workplace safety.

The removed slag material is collected in a bin and can be disposed of as scrap. By performing slag removal separately, contamination in the deburring machine is prevented.

The machines are equipped with an easy-to-use touchscreen control and are ergonomically designed. They remove slag from sheet metal parts up to 600 mm wide using two robust slag breaker rollers that strike the product twice per revolution. The product is then ready for further finishing in the deburring machine.

| DS600 | |||

| Conveyor belt speed | 0.3-5 m/min | ||

| Product fixation | Magnet system | ||

| Minimum workpiece dimensions | 65 x 65 mm | ||

| Maximum workpiece width | 600 mm | ||

| Maximum workpiece height | 150 mm | ||

| Machine power supply | 400 V | 50 Hz | 14 A | 7 kW | ||

| Dimensions (L x W x H) | 1760 x 1610 x 2085 mm | ||

| Weight | 1,120 kg |

A flexible solution for a flexible metal company. See how Haimerl is prepared for the future.

Are you interested in one of our machines but want to see it in action first? Then schedule a non-binding demonstration in our showroom. If visiting our showroom is not possible, you can also send your own products to us for a remote demonstration. Contact us for more information, and we will reach out to you to discuss dates and options.