What is the TwinLine?

The TwinLine is a complete deburring and finishing solution from Q-Fin that allows you to process sheet metal parts on both sides in one line. Two Q-Fin deburring machines are connected with infeed and outfeed tables and wet-operating extraction units. This way, products are automatically deburred and rounded on both sides.

What are the advantages of the TwinLine compared to single-sided processing?

With the TwinLine you save time and handling, as you no longer need to manually flip sheet metal parts. This results in higher production speed, consistent quality on both sides, and less physical strain for operators.

For which sheet metal parts is the TwinLine suitable?

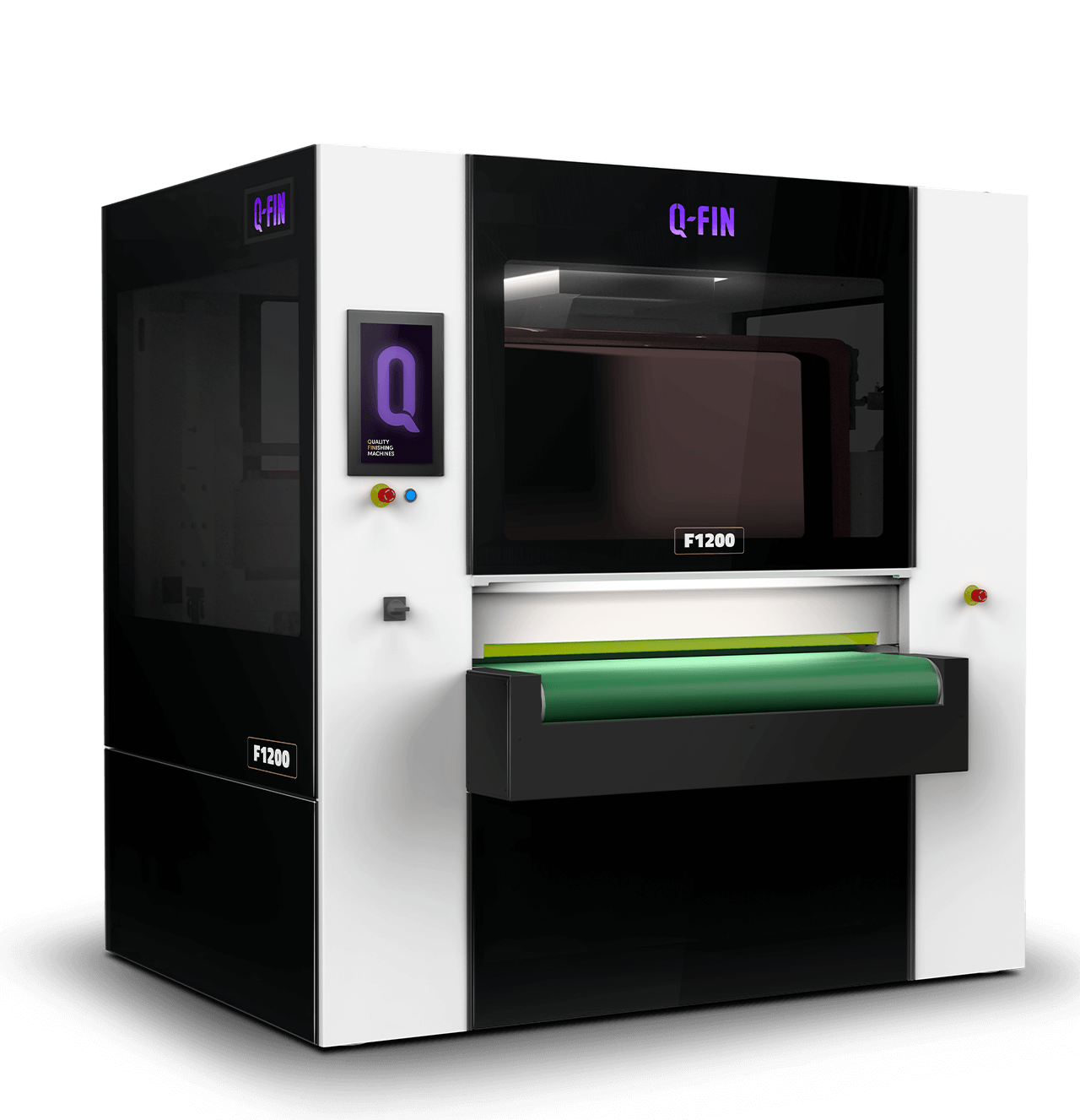

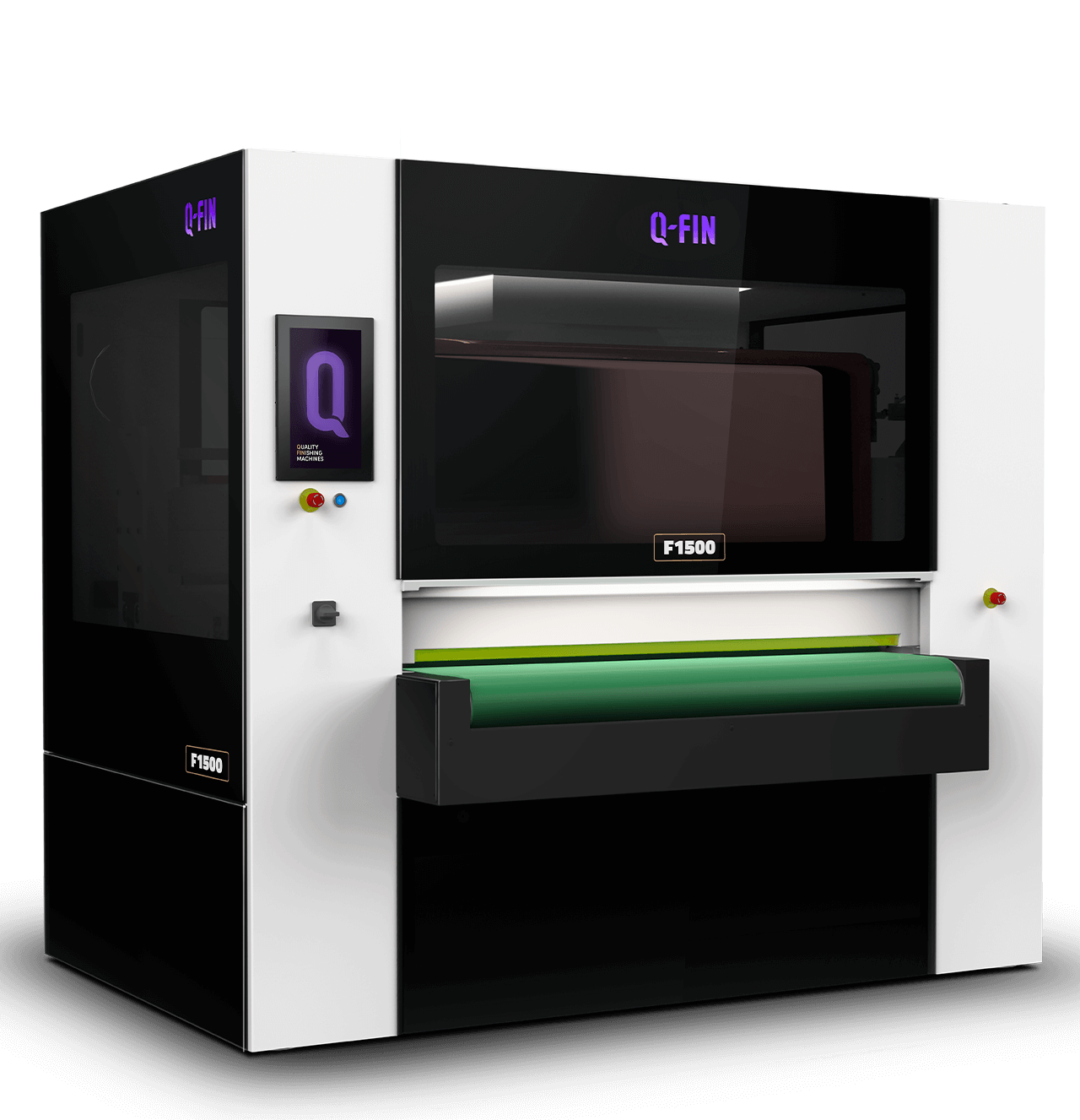

The TwinLine can process sheet metal parts up to a width of 1200 mm or 1500 mm, depending on the selected version. The system is suitable for various materials and thicknesses commonly used in metalworking.

How is the TwinLine configured?

The TwinLine consists of two Q-Fin deburring machines placed in line, combined with a CSI infeed table, a CSO outfeed table, and wet-operating extraction units. Together, this forms a complete, automated production line for double-sided processing.

Is the TwinLine suitable for high production speeds?

Yes, the TwinLine is designed for batchwise infeed and throughput of products. This makes the system particularly suitable for companies that require high output and short lead times.

How does the TwinLine contribute to process optimization?

The TwinLine removes manual handling from the process, reducing the risk of errors and ensuring a more efficient product flow. This results in optimal process control, lower costs per product, and reliable consistent quality.

Can the TwinLine be integrated into existing production lines?

Yes, the TwinLine is designed to be connected to existing Q-Fin machines or new production lines. Depending on the situation, the configuration can be flexibly adapted.

Can the TwinLine be integrated into my existing process?

Yes. The line is designed for inline integration with existing logistics and can be incorporated into many production routes. The exact layout, height transitions, and buffering strategy are tailored to your environment.

What is the difference compared to single-sided deburring?

Single-sided processing requires manual flipping or a separate step. The TwinLine automates this via the Q2S, giving you fewer handling steps, shorter lead times, and higher process stability.

Is the TwinLine scalable or adaptable?

Yes. Component selection (brushes/units), width (1200/1500 mm), table logistics, and extraction capacity are configurable. This allows you to tailor the line to material, edges, radius, and desired output.

What is the impact on ROI/cost per piece?

The TwinLine lowers the cost per part through fewer handling steps, batchwise throughput, reduced scrap, and consistent quality — resulting in higher OEE (Overall Equipment Effectiveness).

Handling

Handling Transportation

Transportation Turning

Turning