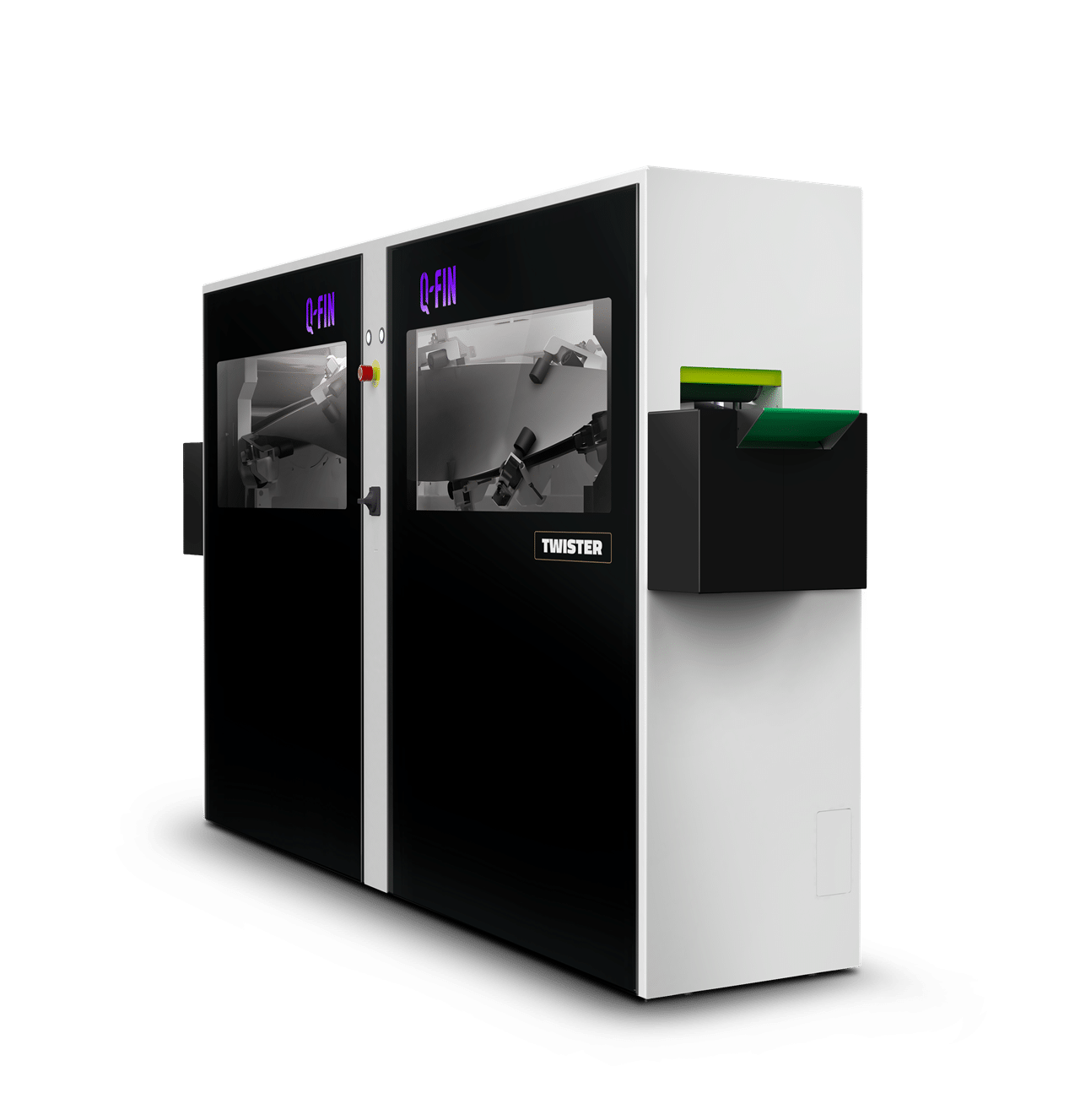

The Twister has been specially developed for those who want to quickly and efficiently reverse small sheet metal parts in an automated finishing line. In combination with two F250 machines, you can achieve double-sided finishing in a single pass – without manual intervention.

This compact flipping unit processes products up to 250 mm wide and ensures a smooth transition between the top and bottom sides of the workpiece. This creates a continuous flow in your production process with higher output, consistent quality, and less physical strain on the operator.

The Twister may be small in size, but it delivers big results. A smart addition for anyone aiming to achieve maximum efficiency when processing small sheet parts.

Handling

Handling Transportation

Transportation Turning

Turning