Highest standards of precision and surface quality

Anyone realizing projects of this size and complexity relies on the highest standards of precision and surface quality. The requirements for deburring are correspondingly high: cleanly rounded edges ensure safe handling, exact fitting accuracy and permanently adhering coatings.

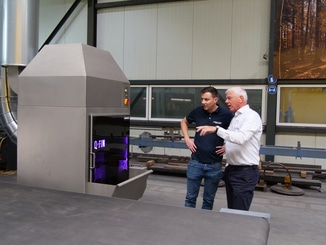

Until the beginning of 2025, however, deburring was mainly done by hand – a labor-intensive and unhealthy process with a considerable risk of injury. “For a current project, we urgently needed to prepare components with a radius of 2 for subsequent painting. It was not economically feasible to do this manually,” reports Johannes Dicks, Design and Project Management at Aquatec. The search for an automated solution ultimately led to Q-Fin B.V., a manufacturer from the Eindhoven region that is breaking new ground with innovative deburring machines.

Just in time for its 25th anniversary, Aquatec is automating edge processing. Steel, stainless steel and aluminum can now be rounded reproducibly with a defined radius 2+ – without the effort of previous manual work.

Just in time for its 25th anniversary, Aquatec is automating edge processing. Steel, stainless steel and aluminum can now be rounded reproducibly with a defined radius 2+ – without the effort of previous manual work.